Automatic polishing machine according to the polishing function is divided into rough cast machine and automatic two fine buffing machine, automatic polishing machine, physical characteristics, processing object according to the data, can be simply divided into: graphic automatic polishing machine, automatic polishing machine, automatic surface polishing machine, steel belt automatic polishing machine, copying automatic polishing machine, automatic polishing machine, revolved plastic automatic polishing machine, acrylic automatic polishing machine, and so on have universal type and special type of distinction.

General purpose and special purpose models are not easy to distinguish. They all have certain universality and specificity. Such as automatic surface polishing machine. In the production, if according to the specific object non-calibration. You can only polish flat objects. As we all know, objects vary in size. When it leaves the factory, the automatic polishing machine’s work surface is fixed. To deal with multiple objects will be subject to now. Therefore, engineers should consider the universality of automatic polishing machine when designing. They are usually designed to the maximum object size. Or design multi-function automatic polishing machine.

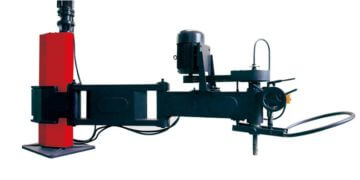

Automatic polishing machine is a kind of automatic polishing machine, which is developed for metal polishing automaticity, using cloth wheel polishing, mainly used for polishing all kinds of non-ferrous metal products including sanitary ware products, instrument products and auto friction products. High performance PLC and man – machine interface are adopted to save labor cost and improve efficiency. Meet CE standard and environmental protection requirement.