Type of Polishing Agent: Although the polishing agent is a special polishing material, its difference from the grinding material is mainly reflected in the processing mechanism. In principle, some low-hardness micro-powder materials can also be used as polishing agents. However, generally high hardness polishing agents are better than low hardness and have a wide range of applications.

Polishing fluid: Water is a commonly used polishing fluid. It acts both as a grinding and cooling agent and as a medium for physical and chemical action in the polishing process. If the polishing of stone is based on mechanical grinding, such as diamond micropowder, the polishing liquid on the stone poliishing machine generally uses oil-based organic liquid, such as sewing machine oil. It has excellent cooling, lubrication and dispersion. Diamond paste, both water and oily, can also be added with colorants.

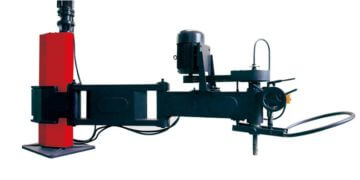

Polishing disc: The flat-paneled stone light panel is an expression processing form of stone surface grinding. Most of the hard disks made of metal materials are used as polishing discs. The polished surface of the floppy disk is easy to yield to a concave surface when the stone is pressed, and is suitable for curved surface polishing. The hard disk has good wear resistance, good adsorption, and certain elasticity, and the polishing effect on the flat stone is also better.