stone Polishing machine, also known as grinders, are often used for mechanical grinding, polishing and waxing. The working principle is as follows: the motor drives the sponge or the wool polishing disc mounted on the polishing machine to rotate at a high speed, and the polishing disc and the polishing agent cooperate with each other and rub against the surface to be polished, thereby removing the paint surface contamination, the oxide layer and the shallow mark. purpose. The rotation speed of the polishing disc is generally 1500-3000 r/min, mostly infinitely variable speed, and can be adjusted at any time according to the needs during construction.

The key to the operation of the polisher is to try to get the maximum polishing rate in order to remove the damage layer from the polishing as quickly as possible. At the same time, the polishing damage layer will not affect the final observed tissue, ie, it will not cause false tissue. The former requires the use of coarser abrasives to ensure a larger polishing rate to remove the polished damage layer, but the polished damage layer is also deeper; the latter requires the use of the finest material to make the polished damage layer shallower, but polished The rate is low.

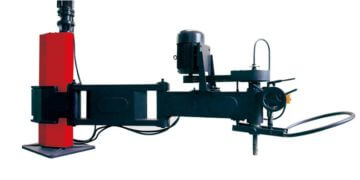

The speed of the turntable can be appropriately increased during fine polishing, and the polishing time is preferably to throw away the damage layer of the rough throw. After fine polishing, the polished surface is as bright as a mirror. No scratches can be seen under the bright field conditions of the microscope, but the wear marks are still visible under phase contrast lighting conditions. The polishing quality of the polishing machine seriously affects the structure of the sample, which has gradually attracted the attention of relevant experts. At home and abroad, a lot of research work has been done on the performance of the polishing machine. Many new models and a new generation of polishing equipment have been developed, which have been developed into various semi-automatic and fully automatic polishing machines from the original manual operation.