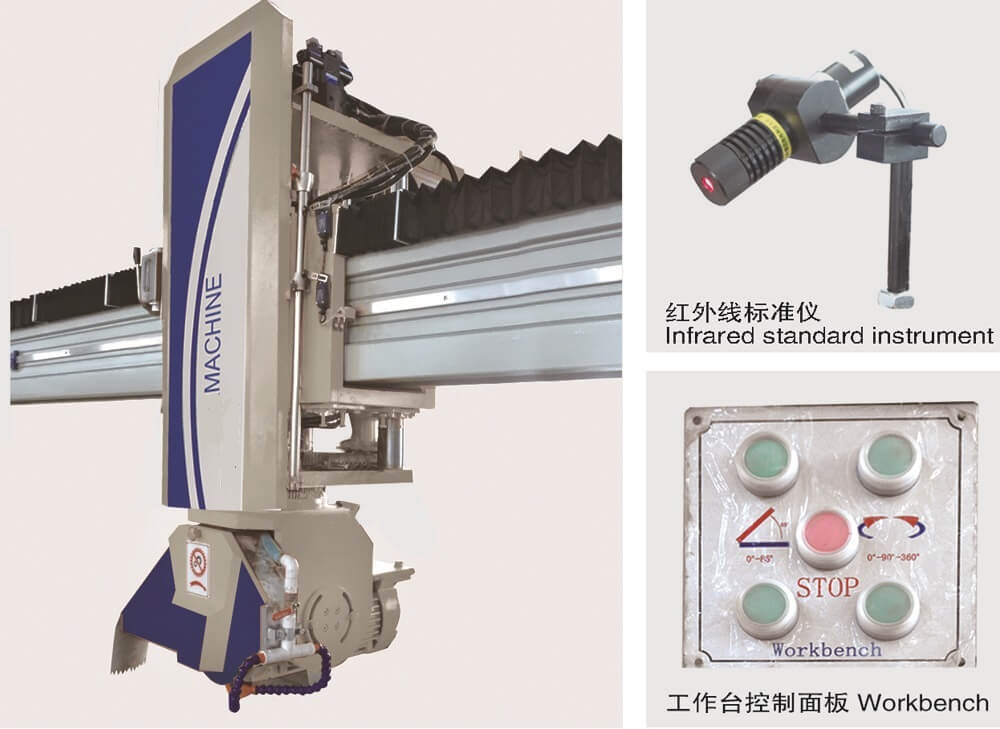

Mono Block Bridge Saw Description

Mono Block Bridge Saw Machine is a saw machine that can do both straight and angle cutting. The machine blade can have a 45 degree tilting cut. This is really a very useful features for bridge saw machine. Compare with other regular saw machine, it collect all machine parts and components into one whole set, so we call it mono block bridge saw. On the regular machine, you could find some machine parts are separate with the main machine, you could find the hydraulic part, and the table parts of machine are separate with main machine on regular machine, but on this mono block bridge saw machine, all the above two parts are combine into machine to be a whole machine. Thanks to this mono block design, it makes machine loading and unloading a more easy job. When we ship out machine to oversea customers, we need to load machine into container, and it is easy and more quickly to load a mono block bridge saw machine. Because it have a smaller dimension and takes a less space in container. It would also more easy to unload it at client workshop.

We know that the mono block bridge saw machine is just like a car. so it is also import to maintain during cutting, to keep machine working in good condition. Here i would like to share some important points about bridge saw machine maintain. First we need to add new lubrication oil at a period time of machine cutting. The lubrication oil is a kind of oil which keep machine gears, screws and bearings to working smooth with any damage, if we don’t replace new lubrication the spare part would be broken quickly. Second it is also important to keep the touch screen away from water. We find some customers touch screen broken after a small time using. The main reasons cause to broken of bridge saw machine screen is water, the screen is just like a mobile phone, water will totally make the screen out of work. Third is we need to check machine cables to make sure they are not broken. There are many cables on mono block bridge saw machine and it will make machine stop working even one small pieces of cable, meanwhile, the it is very danger for worker if there is some cables broken. Last one is we need to keep some spare parts in stock. Once some broken, we can replace it immediately. These spare parts are mainly includes last light, PLC, computer screen, bearings etc.

Mono Block Bridge Saw Details

Mono Block Bridge Saw Specifications

| Blade Blade Diameter | mm | 500 |

| Horizontal and Vertical Travel | mm | 3000 |

| Water Consumption | M3/h | 4 |

| Blade Rotation | n | 90 |

| Table Move up | n | 85 |

| Blade Tilt | n | 45 |

| Power of main motor | KW | 18.5 |

| Dimension | mm | 5800*3500*2250 |

| Total Weight | T | 4.8 |

Mono Block Bridge Saw FAQ

Q: When can my order get ready for shipment ?

A: Normally 20-30 days after receiving down payment, but it can be negotiated if customers need urgently.

Q: How about the quality guarantee period ?

A: one year

Q: How can you guarantee the production quality ?

A: We have strictly quality control system in our production process. All products must be double checked during every manufacturing process. Requirement of customers and quality of products will be full guaranteed.

Q: After I buy the machine, how I can install and operate it ?

A: We strongly suggest customer to ask our engineer to come to help you to install the machines, teach your operator how to operate and maintain the machines.

Q: If machine got problem, what can you support it ?

A: It depends on the problem, usually the process is like this

- phone or email the customers how to settle at first.

- send the good one by Express immediately if spare parts broken.

- if problems still not be settled, we will appoint our engineer to solve the problem on spot.