Automatic Stone Polishing Machine Description

We offer automatic stone polishing machine. Its main advantages are that the machine tool is simple in structure, easy to operate and less investment, but the worker’s labor intensity is large, and the area of plate can be processed is limited. Because the replacement of grinding discs with different particle sizes is determined by eye observation of workers, workers are required to have higher technical level, and the final quality of products varies from person to person. At present, this equipment is mainly used for grinding and polishing of profiled sheets. Multi-head continuous grinding and polishing machine is a new type of advanced grinding and polishing equipment. It can complete the whole process of rough grinding, fine grinding, fine grinding and polishing of stone at one time by installing several different grinding blocks and polishing blocks on the production line. The machine is mainly composed of grinding head, grinding head motor, grinding disc transmission frame, frame, automatic conveyor belt and transmission shaft, master control panel, grinding disc control panel, oil pressure station, water spray cooling device, etc. Continuous multi-head grinding and polishing machine with high degree of automation. The equipment has been widely used at home and abroad for its low labor intensity, high production efficiency, good reliability, low production loss, high processing accuracy and stable quality of grinding and polishing plates.

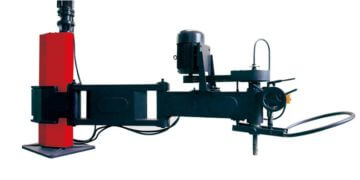

Automatic Stone Polishing Machine Details

Automatic Stone Polishing Machine Specification

| Number of heads | 12,16,20,24 | Pcs |

| Griding disk diameter | Φ220 | mm |

| Max. working width | 1200 | mm |

| Max. woking thickness | 50 | mm |

| Speed of belt | 0.8-2.5 | m/min |

| Power of polishing heads | 7.5 | KW |

| Water consumption | 27 | m³/h |

| Overall dimension | Depends on head number | m |