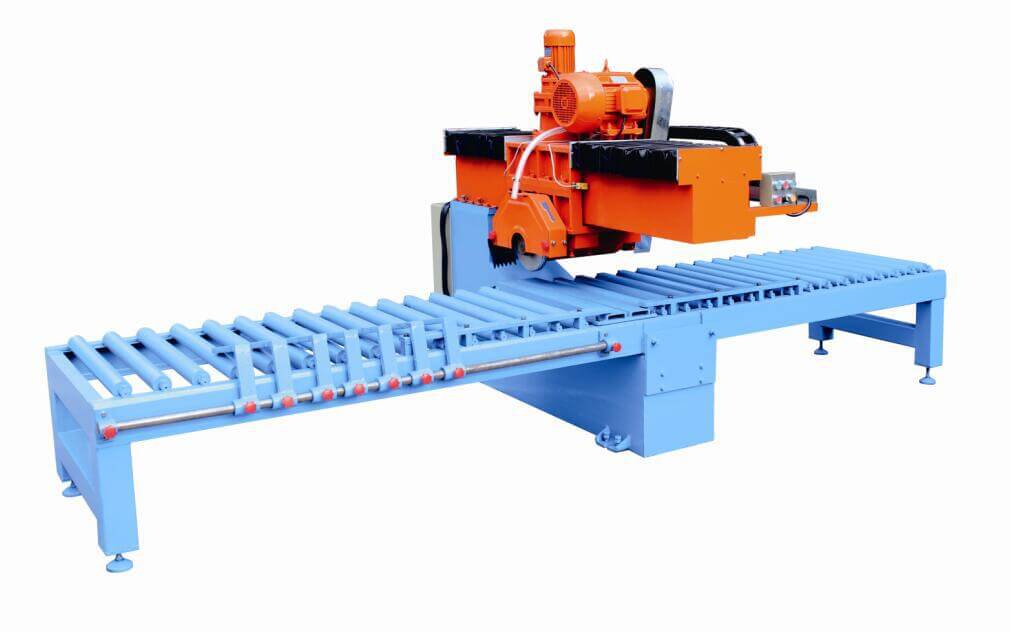

Stone crosscutting machine is one of the important single machine of corrugated board production line. Because of the different transmission control mode of crosscut machine, mechanical crosscut machine and computer control crosscut machine. The computer crosscut machine is controlled by the industrial computer, according to the set length, control the cutter shaft to cut off the paperboard, coupled with the precision transmission of the mechanical part, the paper cutting error can be controlled in the range of 1mm. Computer – controlled crosscutting machine has a spiral knife crosscutting machine, straight knife crosscutting machine. Spiral cutter is more suitable for high speed cutting board, and smooth paper cutting, long blade life.

cross – stone cutting machine is suitable for all types of paper vertical and horizontal cutting. Such as gold and silver card paper, plain rainbow paper, laser security paper, white board and all kinds of thin paper. Widely used in trademarks, cigarette labels, calendars, wine boxes, poker, paper and plastic printing composite materials transverse or longitudinal shear.

Matters needing attention

One, to do a good job in maintenance and maintenance work.

First, the daily maintenance should be in place, the principle is, lubrication, cleaning, cleaning (no dust, no debris) in place, to ensure that the sliding parts of the equipment in good condition.

Secondly, it is the maintenance work, the rotating parts to carry out regular and irregular inspection (especially the wear parts to carry out real-time monitoring). Implement regular adjustment, regular replacement, and make a detailed record, in order to achieve the purpose of extending the service life of the equipment. The electrical parts should be cleaned and inspected regularly to eliminate hidden dangers in time.

Use high quality vertical and cross cutting knives.

- Improve the technical quality and level of the operators. The operators shall be responsible for the operation of the control part.