CNC Stone Engraving Machine description

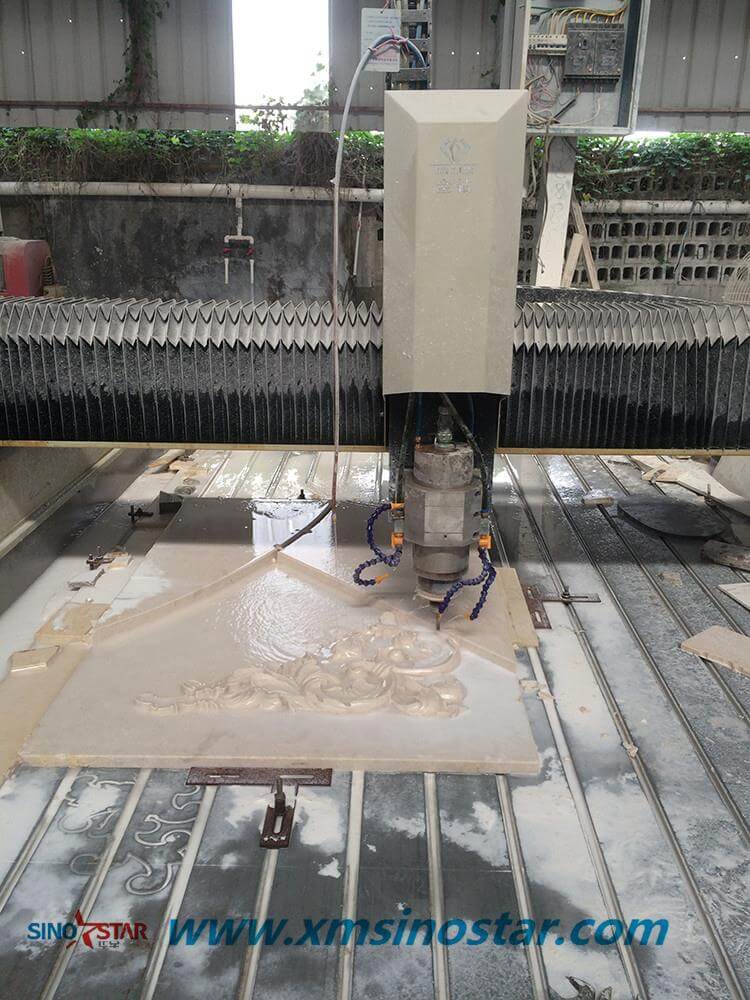

CNC stone engraving machine is suitable for the carving and engraving of marble, granite, ceramic tile background wall, glass, copper, and, etc. It is widely used in stone carving, ceramic tile carving background wall, stone column, handicraft carving, mold carving, etc. There are planes and 3d carving, and also can be multi-head numerical control relief. Here is some introduction to the equipment.

1: It adopts high precision guide rail, double row, and four-row slider, which bears large gravity, runs smoothly, has high precision, long service life, and precise cutting tool setting.

2: T-type engraving structure with strong bearing capacity and small deformation

3: Constant power spindle motor with high cutting and engraving force, high efficiency

4: Good software compatibility, compatible with Typ3/Artcam/Castmate/Wentai and other CAD/CAM design software

5: Two-way tool cooling system to effectively improve tool life

CNC stone engraving machine is precise numerical control equipment so the necessary daily maintenance is very important for the service life and accuracy of the machine. Please maintain according to the following requirements. The first one is to ensure the cleanliness of the cooling water and the normal operation of the water pump. Water shortage of water spindle motor must not occur. Cooling water should be replaced regularly to prevent excessive water temperature. In winter, if the working environment temperature is too low, the water in the water tank can be replaced by antifreeze. Second is cleaning the machine after each use. Dust on the platform and the transmission system must be clean up regularly. Some parts need to change lubrication oil weekly or sometime later.

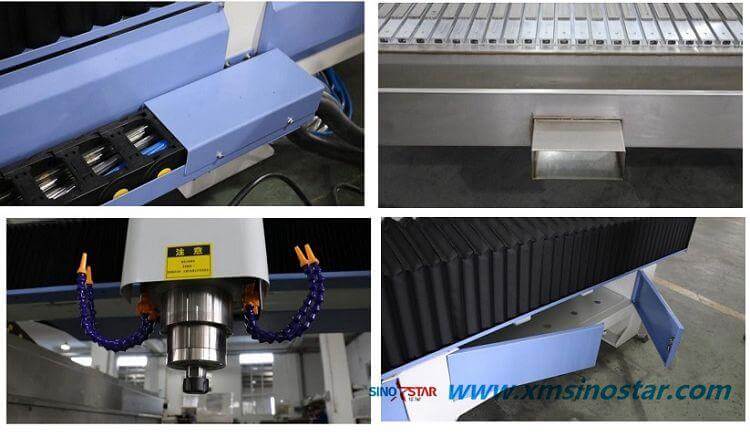

CNC Stone Engraving Machine Details

CNC Stone Engraving Machine Specifications

| X, Y axis travel | 1300 x 2500mm |

| Max. Z axis travel | 260mm |

| Max. Feeding height | 260mm |

| Power of spindle | 4.5kw water cooling |

| Spindle speed | 0-24000rpm |

| Working mode | Stepper(Rack-and pinion rotating) |

| Max operating speed | 10m/min |

| Table Structure | seamless cast steel |

| Processing precision | ±0.05mm |

| Repositoning Precision | ±0.05mm |

| Transmission System | XY Axis advanced rack and pionion,Z Axis ball srew |

| XYZ guide rail | Square linear guide Rail (option:work round guide rail) |

| Working Voltage | Ac380/50Hz |

| Command language | G code.u00.mmg.plt |

| Software campatibility | Type3,Artcam,UcancamV8 |

| Drive motor | Stepper |